BMW to Introduce Figure’s Humanoid Robot at South Carolina Manufacturing Plant

Most people like

Discover the ultimate all-in-one AI app featuring a diverse range of cutting-edge AI models designed to meet your various needs.

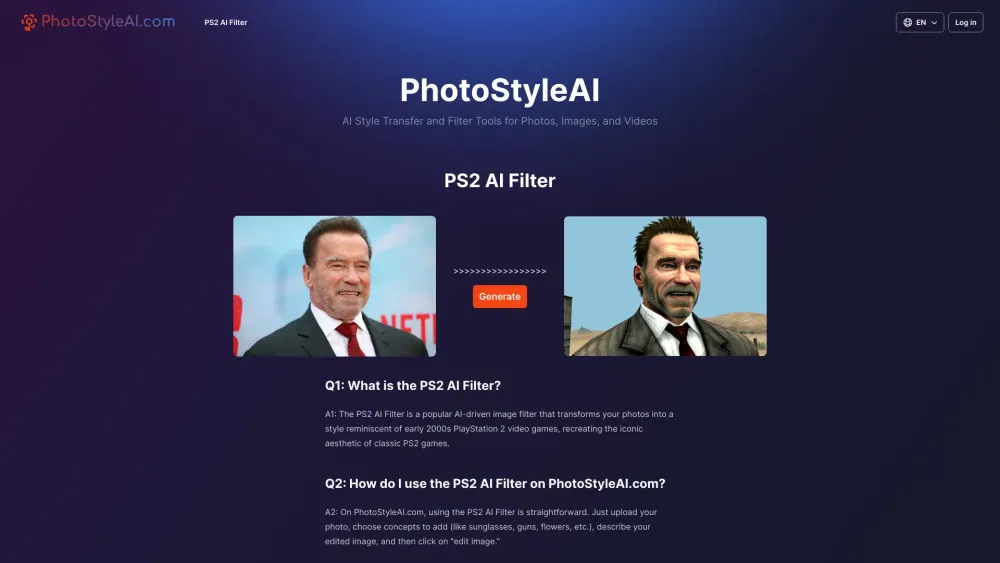

Effortlessly enhance your photos and images using advanced AI style transfer and filter tools. Transform your visuals with innovative technology that brings creativity to life.

Boost Your Job Application with Our Enhancement Platform

In today's competitive job market, standing out from the crowd is crucial. Our innovative job application enhancement platform is designed to help you showcase your unique skills, experiences, and qualifications effectively. With tailored resources and expert guidance, we empower you to create a compelling application that captures the attention of hiring managers.

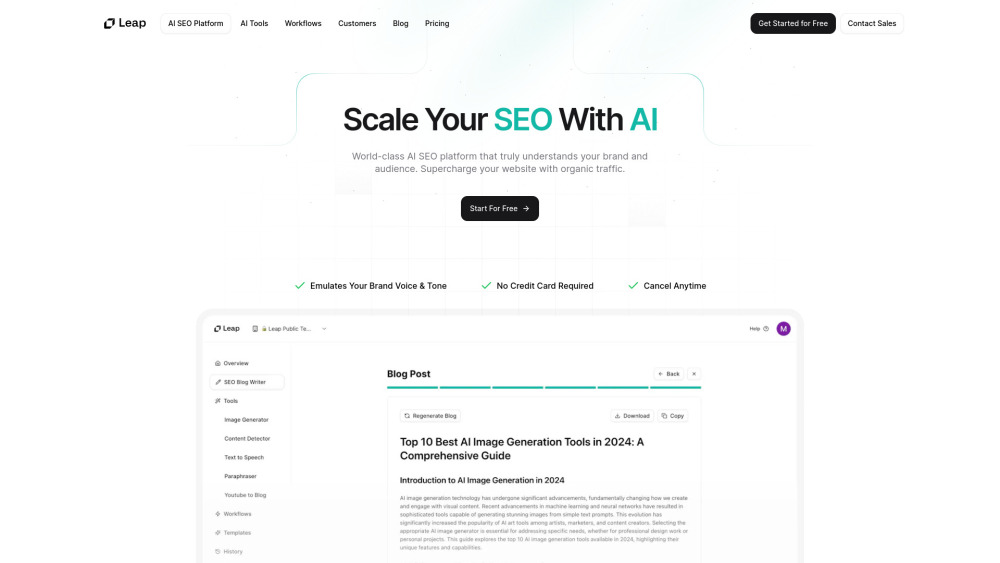

Unlock the potential of your online presence with our advanced AI SEO tool, designed specifically to help you produce high-quality SEO content. Enhance your website's visibility and engagement by leveraging cutting-edge algorithms that analyze trends and optimize your writing for search engines. Create compelling, relevant, and keyword-rich content that resonates with your audience while improving your ranking on search results. Embrace the future of content creation and watch your visibility soar!

Find AI tools in YBX